DX320 is formed by the combination of various polycarboxylic acids and isomeric organic amine. It has significant characteristics such as low addition, low residue, resistance to hard water, resistance to strong alkali and long anti-rust prevention cycle. With excellent rust prevention performance, It is widely used in industries such as metal corrosion prevention, machining, surface treatment, and coating for its excellent rust prevention performance.

Product name | DX320 |

Ionic type | Nonionic |

Appearance (25℃) | Light yellow to colorless transparent liquid |

Density (20℃, g/cm3) | 1.21 |

PH value (1% aqueous solution) | 8.0-10.0 |

Shelf life | 1 year |

2h test of cast iron chips (0.20% aqueous solution) Reference standard: IP287 | Level 0 |

1. Rust prevention performance of 0.8% DX320

2h | 12h | 24h | 48h |

|

|

|

|

2. Carbon steel plate immersed in 0.5% DX309 aqueous solution for one year has no corrosion

Blank control | 0.5%DX320 |

|

|

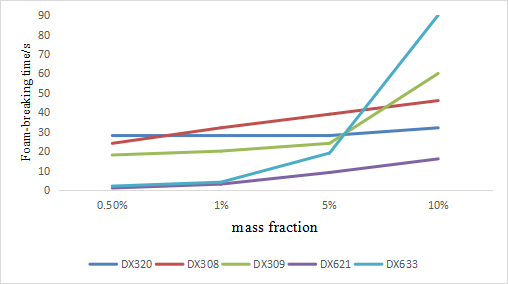

3. Fast antifoaming speed

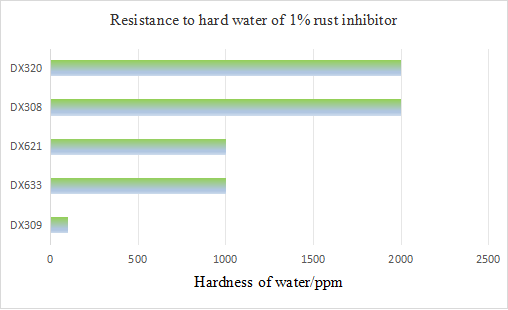

4. Resistance to hard water

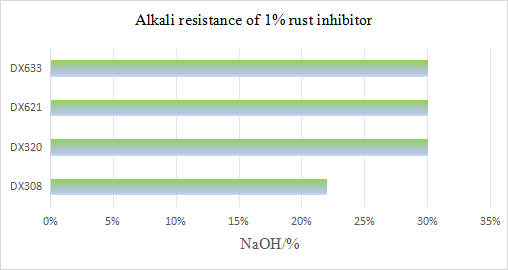

5. Strong alkali resistance, capable of withstanding over 30% concentrated alkali solution, suitable for alkaline cleaning systems to improve rust prevention performance.

1. Application Area

Metalworking Fluid(金属加工液)

Surface Treatment(表面处理)

Water-based Paint(水性漆)

2. Recommended Materials

Ductile Cast Iron(球墨铸铁)

Cold Rolled Plate(冷轧板)

Bearing Steel(轴承钢)

1. 50L plastic bucket, 60Kg/bucket; 200L plastic bucket, 240Kg/bucket;

2. Stored and transported according to general chemicals .Stored in a dry and ventilated place.