DX5810 is a new environmentally friendly multifunctional metal corrosion inhibitor. This product does not contain silicon and is easily soluble in water. It has excellent corrosion inhibition, rust prevention, and extreme pressure lubrication properties, making it an excellent comprehensive additive. Widely used in industries such as machinery, metallurgy, copper wire drawing, petrochemical, construction rust resistance, industrial cleaning, and metal surface treatment, it has a significant positive effect on improving the overall performance of the system.

Product name | DX5810 |

Appearance (25℃) | Amber transparent liquid |

Density (20℃, g/cm3) | 1.05 |

PH value (1% aqueous solution) | 8.5-10.5 |

Shelf life | 1 year |

Corrosion inhibition of aluminium (0.1% aqueous solution) Reference: GB/T6144-2010 | A |

Corrosion inhibition of copper (0.1% aqueous solution) Reference: GB/T6144-2010 | A |

1. Corrosion inhibition performance

The reference standard GB/T6144-2010 was used to test the improvement effect of different contents of DX622 on the corrosion inhibition performance of Ly12 aluminum and red copper

in a basic cutting fluid system. The basic cutting fluid system is: 5% triethanolamine borate, 3% triethanolamine, the rest is water.

0%DX5810 | 0.5%DX5810 | 1%DX5810 | 2%DX5810 |

|

|

|

|

|

|

|

|

2. Rust prevention performance of 1.0% DX5810

2h | 12h | 24h | 48h |

|

|

|

|

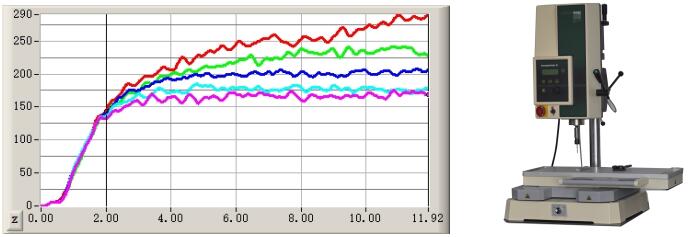

3. Lubricity

mass fraction/% | 0.1 | 0.3 | 0.5 | 1.0 | 2.0 |

Average tapping torque value/N.cm | 239.9 | 214.9 | 194.9 | 174.2 | 164.1 |

1. For fully synthetic and semi synthetic aluminum cutting fluid systems, it is recommended to add 1% -2% DX5810 of the original solution;

2. For organic alkaline systems, it is recommended to add 2% -5% DX5810 of the original solution.

1. 200L iron bucket, 200Kg/bucket;

2. Stored and transported according to general chemicals .Stored in a dry and ventilated place.