DX308 is formed by the combination of various polycarboxylic acids and organic amine, and does not contain phosphorus, boron, and other elements. It has significant characteristics such as no bubbles, resistance to hard water, resistance to strong alkali and acid. It is widely used in industries such as metal processing, surface treatment, and industrial cleaning for its excellent rust prevention performance.

Product name | DX308 |

Ionic type | Nonionic |

Appearance (25℃) | Light yellow to colorless transparent liquid |

Density (20℃, g/cm3) | 1.19 |

PH value (1% aqueous solution) | 8.0-10.0 |

Shelf life | 1 year |

2h test of cast iron chips (0.50% aqueous solution) Reference standard: IP287 | Level 0 |

1. Rust prevention performance of 1.1% DX308

2h | 12h | 24h | 48h |

|

|

|

|

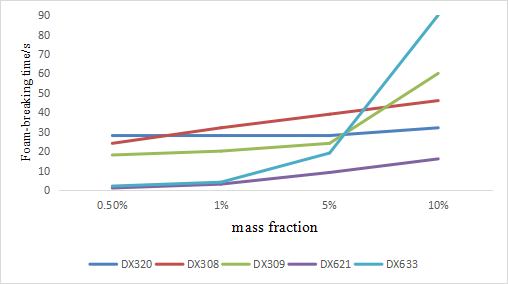

2. Fast antifoaming speed

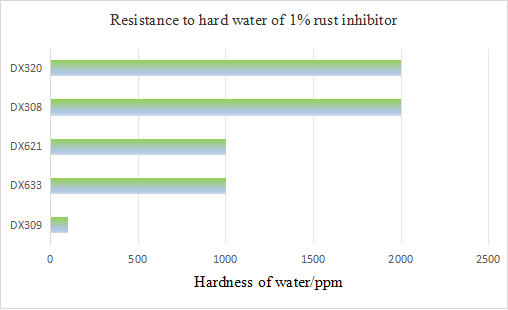

3. Resistance to hard water

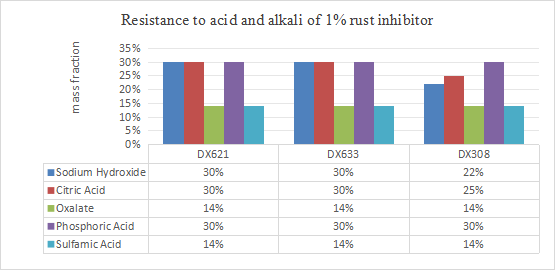

4. DX308 can withstand concentrated 22% sodium hydroxide solution and has good tolerance to commonly used acids such as citric acid, oxalic acid, phosphoric acid, and amino sulfonic acid.

1. For metalworking fluids, it is recommended to add 2% -5% DX308 of the original solution;

2. For surface treatment agents, it is recommended to add 0.5% -1% DX308 of the original solution.

1. 200L plastic bucket, 230Kg/bucket;

2. Stored and transported according to general chemicals .Stored in a dry and ventilated place.