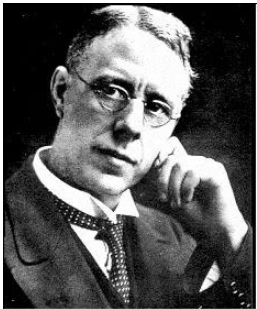

The man in this photo is none other than the "father of stainless steel" — Harry Brearley. In this article, we’ll explore the story behind his invention of stainless steel.

In 1914, World War I broke out, and fierce battles erupted between Britain, France, and Germany.

During the war, British soldiers often had to return their rifles to the rear for repair due to poor steel quality and excessive wear. Repairing these damaged rifles was time-consuming — nearly as long as manufacturing new ones — and throwing them away seemed wasteful, like discarding something that offered little value but was hard to part with: “tasteless when eaten, a pity when thrown away.” Moreover, transporting the broken guns back from the front line was costly and affected combat operations.

This issue troubled the British government, which decided to develop a more wear-resistant gun barrel. The task was assigned to Harry Brearley, a renowned British metallurgy expert at the time.

Once Brearley accepted the mission, he immediately formed a research team to begin work on developing new alloy steels.

Metallurgical research and alloy synthesis were challenging tasks. To complete the project as quickly as possible, Brearley worked day and night.

He experimented by adding various chemical elements into steel, searching for a more wear-resistant alloy. To test the properties of the new alloys, he conducted performance tests on different types of machinery, selected suitable materials, and used them to produce rifles for live-fire testing at shooting ranges.

For a long time, however, Brearley’s research made no real breakthroughs. Discarded pieces of failed experiments piled up in the lab like a small mountain.

“All the experiments have failed! Why is this happening?” Brearley fell into deep frustration. But soon, he regained his composure and told himself:

“No, I mustn’t lose heart. It’s not that we’ve made no progress — at least now we know many types of alloy steel are unsuitable for making gun barrels.”

Reinvigorated, Brearley decided to clean up the lab to prepare for new experiments.

The entire research team got to work. They started by clearing out the pile of discarded metal scraps. With everyone pitching in, the scrap pile quickly began to shrink.

“Strange!” one researcher suddenly exclaimed. “Why is this piece of alloy steel so shiny and bright, without any rust at all?”

“I’ll check it!” Hearing this, Brearley rushed over, followed by the rest of the team.

“It really is strange,” Brearley mused. “Why is this one standing out?”

“Let’s check its ‘identity’ — its composition!”

Everyone hurriedly brought out the lab notebooks and searched through the records. After some effort, they identified the composition of this particular alloy. It turned out to be a chromium alloy. Because it was not hard enough and wore easily, Brearley had previously rejected it.

“It doesn’t rust — meaning it resists air corrosion. Then what does corrode it?” Curious, Brearley immersed the alloy in acid, alkali, and salt solutions. The results showed that it resisted all three — it was highly corrosion-resistant.

To be thorough, Brearley produced another identical chromium alloy and retested both its wear resistance and corrosion resistance. The results matched those of the original sample.

“This isn’t wear-resistant enough for making rifles,” said Brearley’s assistant. “But since it's so corrosion-resistant, maybe we can use it for something else instead? That way, nothing goes to waste!”

“What could we make?” Brearley thought for a moment, then remembered the knives and forks at home that always rusted after short use.

“That’s it! Cutlery would be perfect!”

Although rifle material development remained Brearley’s top priority, during breaks or late at night while others were having coffee or sleeping, he fashioned the chromium alloy into a fruit knife.

This was the world’s first stainless steel product!

Everyone who tried the knife found it excellent for cutting fruit. More importantly, even after extended use, the blade remained shiny and as good as new.

Brearley became even more motivated. He went on to create stainless steel knives, forks, spoons, and other cutlery, which were warmly welcomed and quickly became popular items.

Meanwhile, Brearley also succeeded in finding an alloy steel suitable for making gun barrels, successfully producing a new generation of wear-resistant rifles. Thus, he was praised for achieving success both in his main research and in this side project — “making full use of both useful and discarded materials.”

In 1916, Brearley obtained a British patent for stainless steel, and mass production began shortly thereafter. From that point on, stainless steel — discovered almost accidentally among discarded scraps — began spreading globally. Harry Brearley was henceforth honored as the “father of stainless steel.”

Disclaimer: This article is reprinted from the official WeChat account 【Metal Materials World】(ID: ijinshu). Our website assumes no responsibility for the content. If there is any copyright infringement, please contact us to request removal.

Contact: 020-82118890